Why Mozaik Manufacturing™ plus Optimizer?

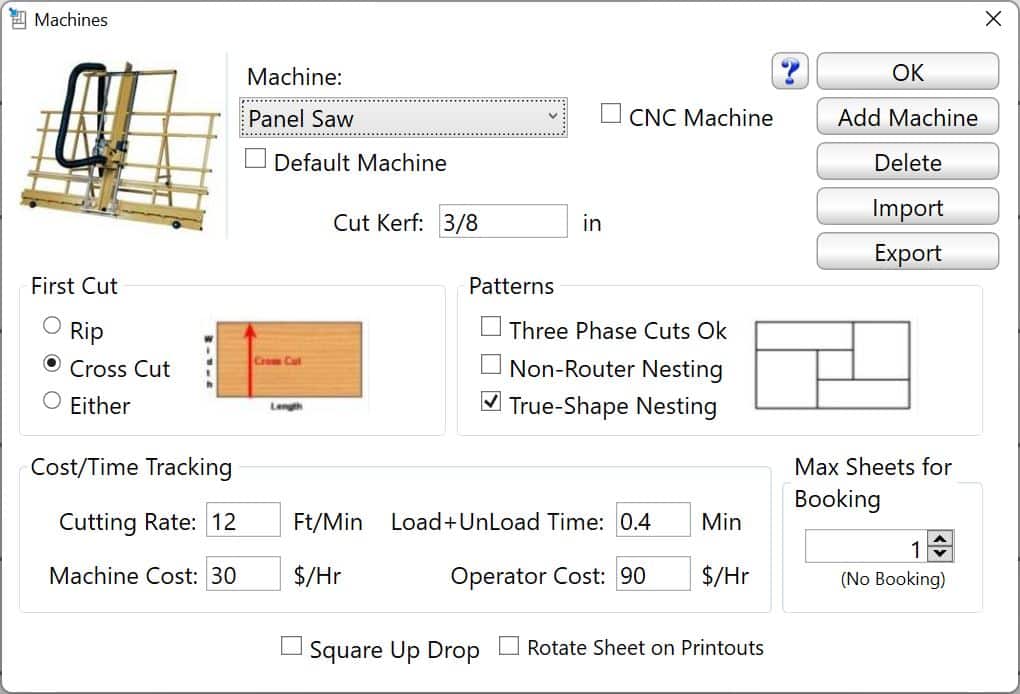

Optimize for table or panel saw processing

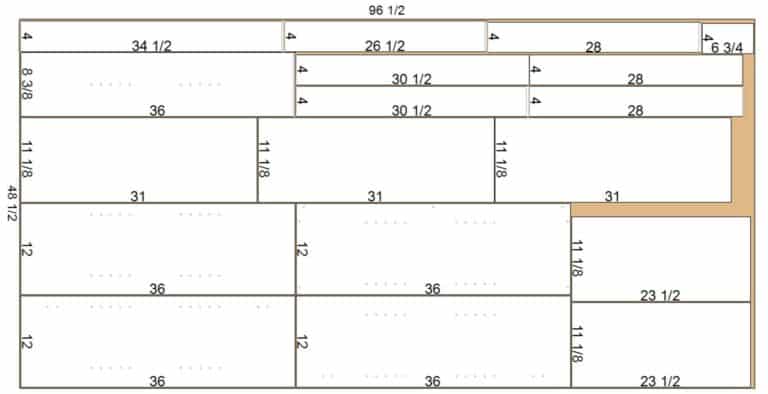

Set your saw optimization parameters for first cuts to be Rip Cuts, Cross Cuts or Three Phase Cutting options. Advanced “Saw Nesting” allows for complex cutting on manual table saws. Irregular-shaped parts can be nested using the true-shape nesting feature. Parts can be grouped for better yield and grain matching.

Grain matching

Make quick work of grain matching doors and drawer fronts. Choose from vertical or horizontal grain direction and let the Optimizer do the hard work.

Use the drag and drop feature to move parts on the nest, bump the parts into place to within tool tolerance. Copy and paste parts from one sheet to another. The Mozaik Optimizer is the perfect blend of advanced automation and manual control.

Part export options

Export your parts or patterns to a variety of file formats for manufacturing with Beam or Panel Saws, or thru feed CNCs. You can “Book” your patterns to process multiple identical sheets at once. Square up your off cuts and create remnants for use with future jobs. Simply right click on an open area in the sheet, check the appropriate box and you’re done. Fast. Simple. The way software should be.